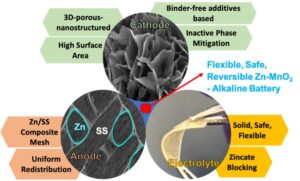

1. Safe and Flexible Rechargeable Zinc Batteries

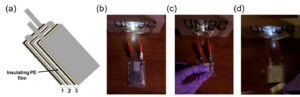

The next-generation flexible wearable electronics are among the most rapidly growing industries due to their extended use in everyday applications resulting in an increased demand for cheaper, safer, and flexible energy storage devices. This study aims to investigate and enhance the overall performance of a Zn-MnO2 alkaline battery and make it suitable for safe and flexible wearable applications. To achieve high cyclability and performance of the cathode, issues of low active-material availability for redox reactions and inactive-phase formations were overcome by fabricating binder-free hierarchical (increased surface area) additives (enabled reversible compound formation) based MnO2 cathode. Furthermore, Zinc/Stainless steel composite anode (to reduce anode shape changes) and calcium hydroxide-coated polymer electrolyte (to stop zincate ion transfer) were used to improve cyclability. By assembling above -mentioned layers, excellent rate capabilities, and high-capacity utilization are achieved. Moreover, bending, hammering, puncturing, and lighting up an LED are conducted (under flat, bent, and cut) to demonstrate the cells’ extreme safety, flexibility, reliability, and robustness. The successful findings in this study can chart new pathways to the development of safe, flexible, and cost-effective next-generation energy storage sources for wearables.

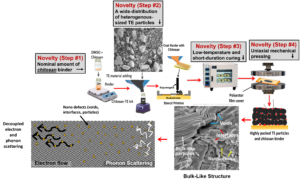

2. Flexible Thermoelectric Materials and Devices (Energy Harvesting Devices)

This research project aims to decouple and independently control electron- and phonon-transport properties by modifying the composite micro-/nanostructure using interfacial engineering and low-energy-input additive manufacturing methods. An essential aspect of this research is that it promises to eliminate the need for the state-of-the-art long-duration (up to 18 hours) and high-temperature (up to 500 °C) curing process (without adding new energy-intensive processes) used in the additive manufacturing of composite thermoelectric films.

We use these materials to print flexible electronic devices (e.g., flexible thermoelectric generators). We focus on cost-effective, earth-abundant, and safe materials, and large-scale production-worthy manufacturing techniques to fabricate flexible and scalable Thermoelectric generators (f-TEG). These devices find applications in wireless sensor networks, health-monitoring sensors, medical devices, automobile engines, condition-monitoring sensors, and defense equipment.